The defense industry has prerequisites similar to the aerospace industry. It calls for by far the most rugged materials demanding high quality precision machining. The applications are wide and diversified, from new weapons prototypes to full missile systems.

As the planet moves in the direction of greener energy solutions, CNC machines will Perform a crucial job in the event and manufacturing of renewable Vitality technologies.

CNC technology was adopted early within the automotive industry, with main automakers purchasing CNC machines to improve production performance and cut down prices.

There are various other expenditures, including the Expense paid out on the designer for the Computer Aided Manufacturing (CAM) blueprint, the hourly labor cost of a precision machinist according to the precision machinist’s skills, and a lot more.

there are actually different sorts of primary milling functions that we can easily use for machining. The followings are a few of the simple milling operations.

EDM applications usually include the hardest metals on account of The issue of machining them applying milling machines. EDM is usually placed on build holes, slots, and tapers in gears.

Multi-axis CNC machining is an entire machining system. The cutting tool can shift in four or maybe more Instructions. Multi-axis CNC machining enables the development of complex parts making use of numerous cutting tools and procedures like milling, waterjet cutting, or laser cutting.

It's a subtractive manufacturing process the place the machine begins with a block and gets rid of substance from it using a cutting tool. Precision machining is commonly used for making an assortment of parts that healthy and work alongside one another.

Our seem good quality-Management system makes sense that Countless customers put their CNC machining orders within our business. The regular Look at and screening begins from incoming materials to cargo, ensuring each aspect is developed accurately for your requirements.

Besides the moving headstock, a sliding guidebook bush moves alongside the workpiece’s longitudinal axis. The guiding bush supports the workpiece through high-precision machining.

Yu has traveled to Russia often in the last decade on small business, his social networking posts clearly show. A single graphic from a trip to Moscow in 2012 displays Yu and Bredikhin, in addition to a former co-proprietor of Bredikhin’s firm.

Among the list of significant advantages of outsourcing manufacturing to 3ERP is that the portion is made with the most higher-conclusion CNC precision machining equipment. Customers gain from the features of this advanced equipment without any want to speculate in First paying for prices.

The workpiece spins about a central axis in CNC turning although a linearly relocating cutting tool removes materials in the workpiece. In contrast to CNC mills, the cutting tool is Usually non-rotary. One-issue cutting tools are most commonly used On this operation.

After the designs in CAM format are comprehensive, it is actually the perfect time to set up the machine. This will usually necessitate machine tool calibration and mounting the more info workpiece within the machine. The machine tools used differ with regards to the workpiece substance and closing product structure.

Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Romeo Miller Then & Now!

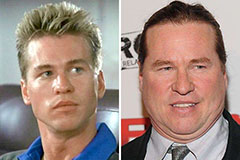

Romeo Miller Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!